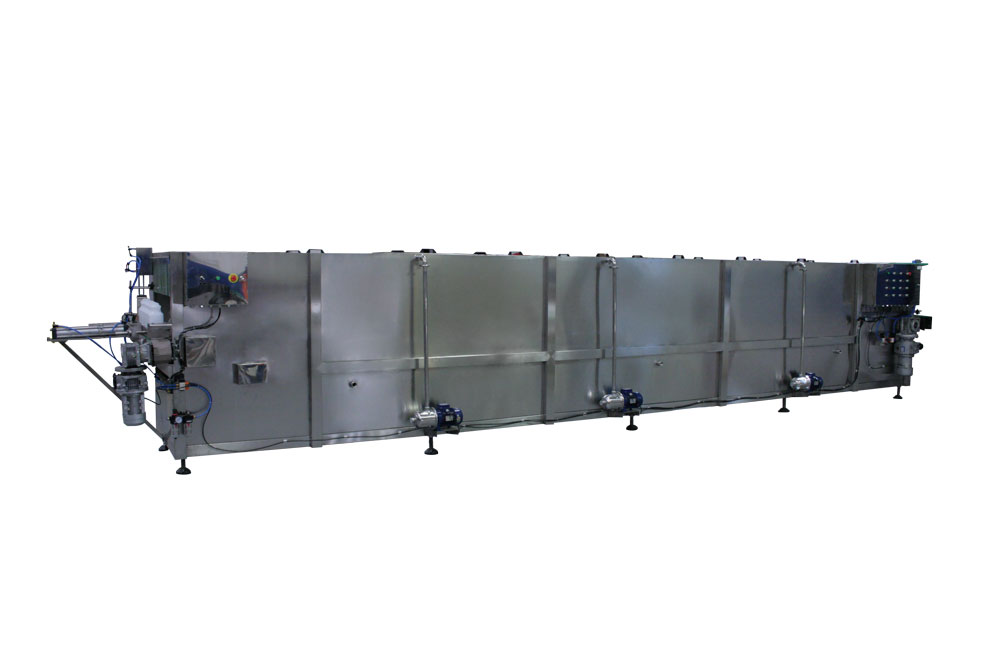

Cooling Tunnel

The Accutek Cooling Tunnel is designed to expedite the cooling of product in PET containers on hot-fill production lines. The cooling tunnel uses a water spray system to rapidly reduce product temperature after filling.

This helps to prevent adverse changes to the product from prolonged heating and is crucial to maintaining the product’s integrity and flavor. Cooling the containers also allows for easier and quicker downstream labeling and packaging. The cooling tunnel uses a three-stage/zone design for maximum efficiency, plus water and power conservation.

Contact Accutek today to learn more about this machine.

Recommended Products

- Bottled products

- Cased products

- FAQ

- Specs

- Features

- Options

- Reviews

- Solutions

How should I clean and maintain this machine?

We recommend performing the following procedures when cleaning and maintaining the cooling tunnel:

- Lubricate the bearings

- Adjust the chain channel and bearings

- Clean the machine

- Inspect the reducer’s oil level

- Inspect the nozzles

What should I do if the machine malfunctions?

If the machine is not operating as intended for any reason, contact Accutek’s service department. We’ll be happy to assist you in troubleshooting the issue and getting your production process back on track.

- Production Speed: Variable

- Electrical: 220V, 60 Hz, 3p, 17A

- Water Requirements: 2000- 3000L per hour

- Height: 55.25” (140.3 cm)

- Length: 35.1” (89.15 cm)

- Width: 43.5” (110.5 cm)

- Weight: Approx. 5500 lbs. (2494.75 kg)

- Stainless-steel construction

- Temperature-resistant conveyor

- Hot water recycling system

- Sealed electrical cabinet

- Three-zone/stage design

- Cooling towers available

- Indexing system infeed

- Indexing system discharge

- Moisture-removal systems for container exteriors

Request a Quote

- Packaging Machines

- Bottling Machines

- Filling Machines

- Capping Machines

- Labeling Machines

- Conveyors and Turntables

- Material Handling

- Sleeving Machines

- Shrink Tunnels

- Mono Block

- Sealers

- Support Equipment

- Washers and Rinsers

- Form, Fill, and Seal

- Inspection-Rejection Station

- Marking and Coding System

- Cooling Tunnels

- Bakery Equipment

- E-Cigarette Equipment

- Used and Demo Equipment

- Services

- Company & Resources

Phone: 760.734.4177

Email: Sales@AccutekPackaging.com

Cooling Tunnel

Product Description

The Accutek Cooling Tunnel is designed for expedite the cooling of product in PET containers on hot fill production lines. The cooling tunnel utilizes a water spray system to rapidly reduce product temperature after filling.Full Description

The Accutek Cooling Tunnel is designed to expedite the cooling of product in PET containers on hot-fill production lines. The cooling tunnel uses a water spray system to rapidly reduce product temperature after filling. This helps to prevent adverse changes to the product from prolonged heating and is crucial to maintaining the product's integrity and flavor. Cooling the containers also allows for easier and quicker downstream labeling and packaging. The cooling tunnel uses a three-stage/zone design for maximum efficiency, plus water and power conservation. Contact Accutek today to learn more about this machine. Recommended Products- Bottled products

- Cased products