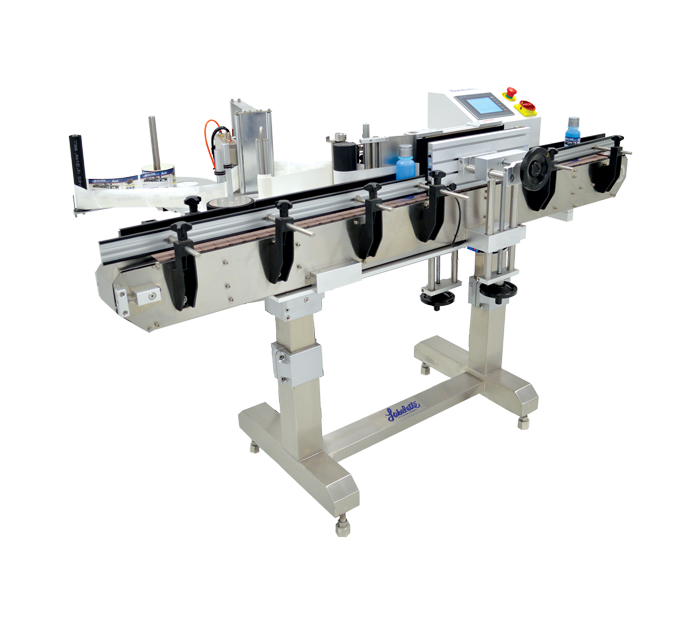

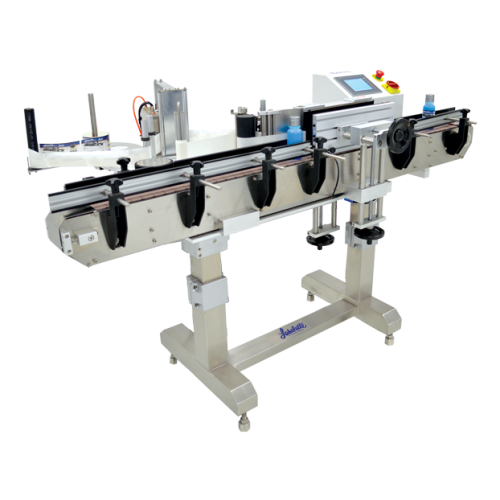

APS 106

Product Variants

Labelette’s APS-106 top labeler is economical, self-contained, and easy to operate. This automatic labeling system has a height-adjustable four-foot variable-speed belted conveyor.

The simple-to-use design makes it simple to change container and label sizes.

The APS-106’s easy-to-use design makes changing bottle and label sizes simple. It can dispense labels up to 5.75” tall and is available with one or two labeling heads for single or front-and-back containers. The machine can perform partial or complete wraparound of one label.

This machine’s speed, versatility, and reliability exceed those of other industry leaders in labeling equipment technology, usually at a fraction of the price.

Our labelers are ideal for all plastic, metal, fiber, and glass containers. The APS-106 handles cylindrical containers.

Contact Accutek today to learn more about this machine.

- FAQ

- Specs

- Features

- Options

- Reviews

- Solutions

Is the touchscreen interface easy to use?

How am I supposed to mount my label reel onto the machine?

What should I do if I have a problem with the machine?

How often should I clean and maintain my machine?

- Labeling Speed: Up to 165 CPM

- Label Length: 0.5” – 15” (1.27 cm – 38.1 cm)

- Label Height: 0.5” – 5.75” (1.27 cm – 14.61 cm)

- Labeling Direction: Left side off – Outside peel

- Electrical Requirements: 110 VAC, 10 AMPS (220 VAC optional)

- Air Requirements: None

- Length: 80” (203.2 cm)

- Width: 28” (71.12 cm)

- Height: 42” (106.68 cm)

- Weight: ~347 lbs (157.4 kg)

- Auto Label Learn™ (automatic label setup)

- Label head dispenses up to 5.75″ (14.61) tall labels

- Touchscreen control system with job memory

- Heavy-duty construction for three-shift operations

- Sanitary stainless-steel frame

- Easy-adjusting hand wheels for quick setup

- Fully synchronized conveyor/label head, with eight different speed selections

- Height-adjustable conveyor

- Maximum roll diameter of 13.5″ (34.29 cm)

- Hot stamp coder

- Pneumatic separator

- Three-roller system (registration and long labels)

- Clear label sensor

- Anti-static device

Related products

Labelette HG

The labeling machine Labelette HG Labeler will index labels, transfer adhesive, and accurately apply a plain paper label to a container.

Labelette HG

The labeling machine Labelette HG Labeler will index labels, transfer adhesive, and accurately apply a plain paper label to a container.

Labelette SG

The labeling machine Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container.

Labelette SG

The labeling machine Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container.

SPS-106 Labeler – Top-down Labeler

Labelette’s SPS-106 Table Top, Top-down Labeler is an economical and efficient countertop labeling machine for top side labeling of rectangular labels.

SPS-106 Labeler – Top-down Labeler

Labelette’s SPS-106 Table Top, Top-down Labeler is an economical and efficient countertop labeling machine for top side labeling of rectangular labels.

Labelette SPS-104 with Thermal Printer

The Labelette SPS-104 Tabletop Labeler with Thermal Printer is a compact and efficient labeling machine designed for round containers.

Labelette SPS-104 with Thermal Printer

The Labelette SPS-104 Tabletop Labeler with Thermal Printer is a compact and efficient labeling machine designed for round containers.

Request a Quote

- Packaging Machines

- Bottling Machines

- Filling Machines

- Capping Machines

- Labeling Machines

- Conveyors and Turntables

- Material Handling

- Sleeving Machines

- Shrink Tunnels

- Mono Block

- Sealers

- Support Equipment

- Washers and Rinsers

- Form, Fill, and Seal

- Inspection-Rejection Station

- Marking and Coding System

- Cooling Tunnels

- Bakery Equipment

- E-Cigarette Equipment

- Used and Demo Equipment

- Services

- Company & Resources

Phone: 760.734.4177

Email: Sales@AccutekPackaging.com

APS 106